Full Service Electrical Engineering Consultant

CD Electronic Designs LLC.

724.288.8693

We can help you with your electrical engineering challenges.

Analog and Digital Circuit Design

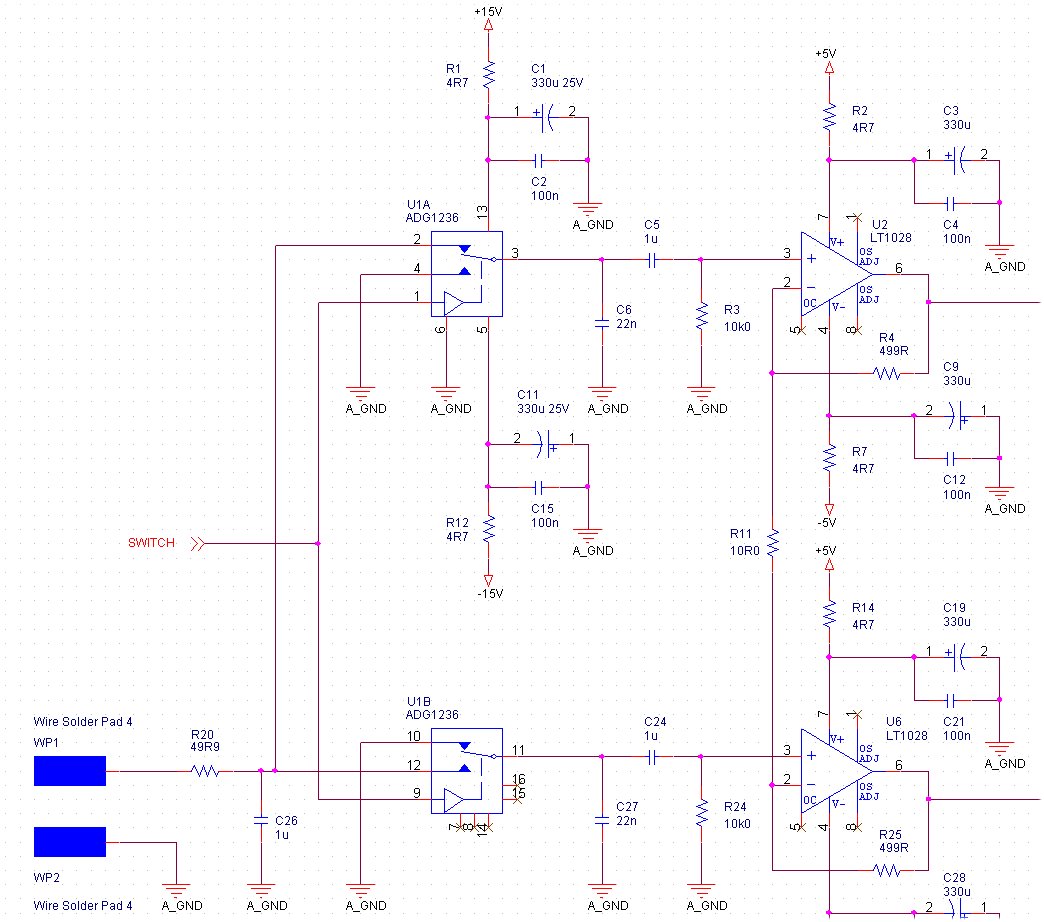

All types of analog circuits from specialty low noise high gain, low drift amplifiers to high efficiency battery supplied switching power supplies. All circuits are custom designed to your specifications.

Applications can be targeted for many different operating systems including Windows, MacOS, iOS, and Android platforms. Application complexity can range from robust commercial level to small in-house helper apps.

Software

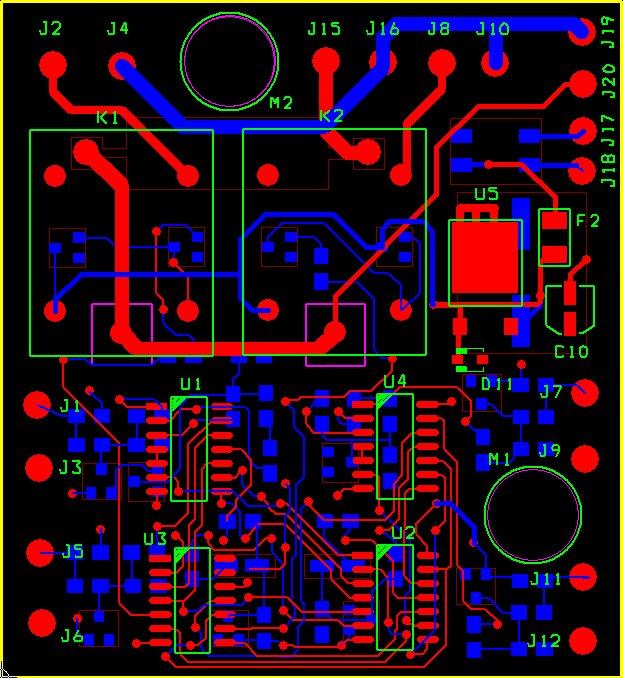

PCB layouts can include single to multi-layer, and through-hole and SMD components. Both high and low density. Board shapes can be made to fit your custom enclosure. Feature width can be made to accommodate fine pitch components.

Schematics are well organized and all part symbols are representative of the actual part, not simply rectangles with pin numbers. Design goals such as cost sensitive, high volume to robust commercial and industrial designs. Circuits can be designed to meet UL, CSA and IEC certifications including EMC, Safety and Intrinsically Safe certifications.

Designs can include eight to 32 bit microprocessors and microcontrollers incorporating all common interface busses such as IIC, SPI, Ethernet, USB, Blue Tooth, E/IP (Industrial Protocol), RS-485 and MODBUS. Designs can also include any available peripheral devices and technologoies such as EEPROM, Flash memory, touch screens and mp3 audio.

As with the circuit design, PCBs can be designed to meet UL, CSA and IEC certifications including EMC, Safety and Intrinsically Safe certifications.

Services can include part selection based on your existing inventory or optimally selected. BOM maintenance may include part number assignment and new part creation.

All code is professionally written, fully commented and easily maintained. We do not require you to provide us with pre-made libraries that do all of the hard work to fill developer knowledge gaps. We can custom design libraries or use commercial packages depending on your requirements.

Firmware

Firmware typically written in C, C++ and assembly to support many of today's popular microcontrollers and microprocessors from Microchip, Texas Instruments and many others utilizing both bare metal and RTOS systems. A variety of compilers can be used.

Over 20 years of experience in the electrical engineering field.

PCB Layout

Debugging and Modification of Existing Designs

Failure Analysis

Many times projects or products may require specialized knowledge to complete or require more time than originally planned for. We can provide the extra capacity to get your project fully functional.

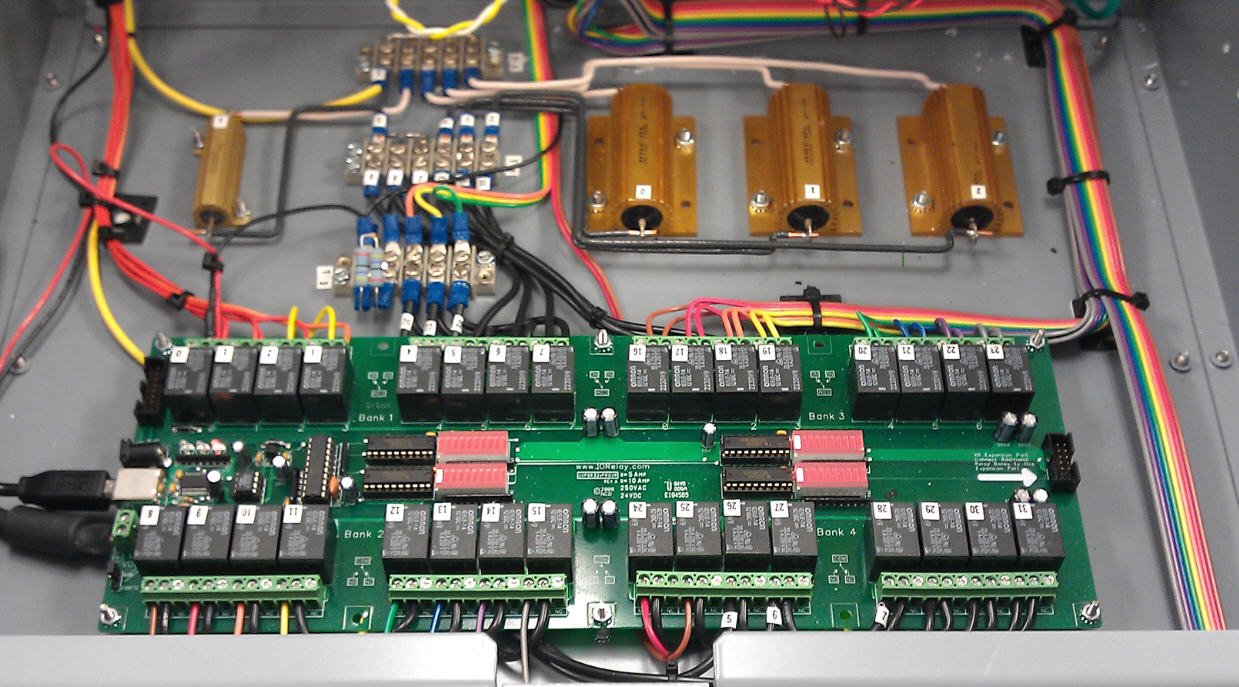

Test Fixture Design and Construction

Test and assembly fixtures are often needed to efficiently test both hardware and software designs. Fixture complexity can range from the very simple to very complex including embedded firmware and hardware, PC interfaces and net connectivity as well as custom mechanical packaging.

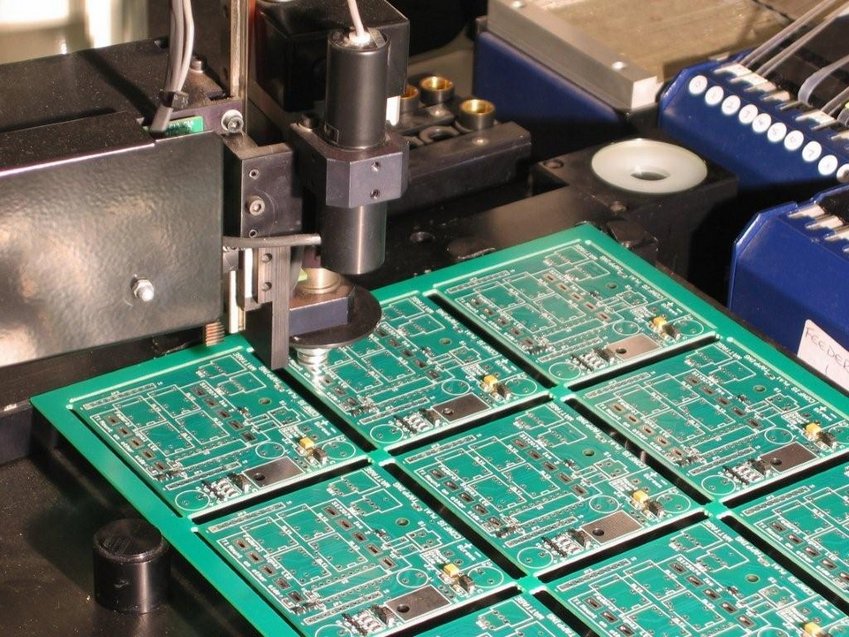

Prototype Builds and Small Production Runs

Light Machining, Metal, Plastic, and Wood Work

V&V Writing and Execution for Firmware and Software

An integral part of any piece of robust firmware or software is testing: verifying that it complies with the requirements and is bug free. Very often custom hardware and/or test software can greatly reduce the test time and improve test accuracy. We can provide both the test procedure and execution in addition to any peripheral software of hardware requirements. We can also coordinate with your development team to meet all of your needs.

CEM Coordination

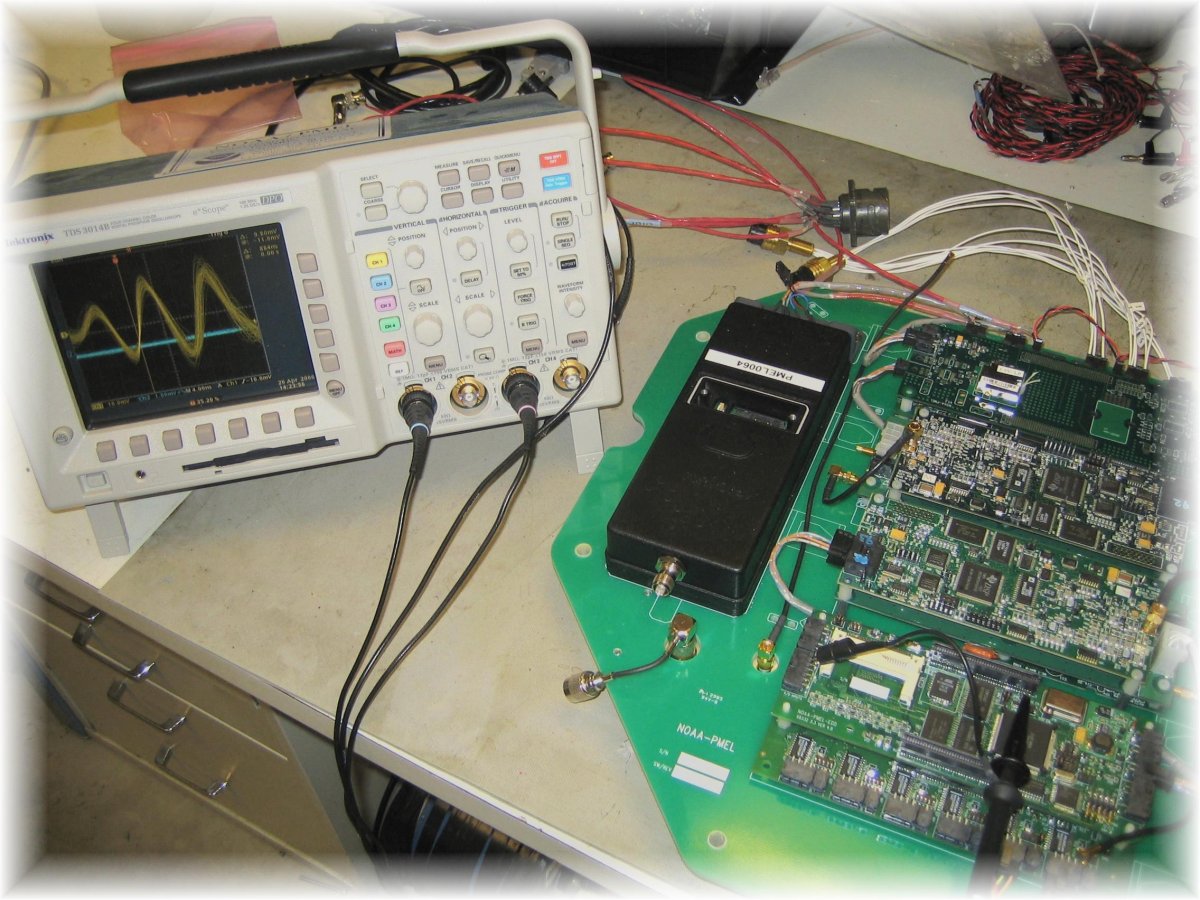

Circuit Design Validation and Testing

Older designs often need modernized or upgraded for many reasons including changes in user requirements, parts obsolescence, changes in UL, CSA, or IS certification requirements, or to simply use the newest technologies. We can assist you with these challenges.

Determining why a design is failing during beta testing or after a product has been released can often be a time consuming task. We can provide the help to determine the root cause of design failures and recommend and implement the necessary changes to create a robust design.

After a design is completed typically one or more prototypes are built to facilitate in-house testing and field beta testing. We have the capability to build prototypes and small production runs of typically ten units.

In addition to fixture and prototype builds we can offer a broad range of light machining for any need that your project requires including lathe and mill work for metal, plastic and even wood, plus hard soldering and welding.

We can coordinate with your existing CEM or completely handle all aspects of your projects production including bare board, PCB assembly, and box builds to provide a complete turn key solution including on-going support such as component substitutions due to lack of availability, are EOL, or for product improvement.

Just like software and firmware, circuits designs need tested and validated. Before a design is completed this can often be accomplished through SPICE simulation. After the initial testing and a prototype is constructed physical testing is often required to fully exercise the design, many times requiring special software or hardware to complete. We can provide any need that your design requires during the testing phase including working with outside resources to perform ALT and EMC testing.